Advanced Moisture Sealing Tape for Complex Surfaces

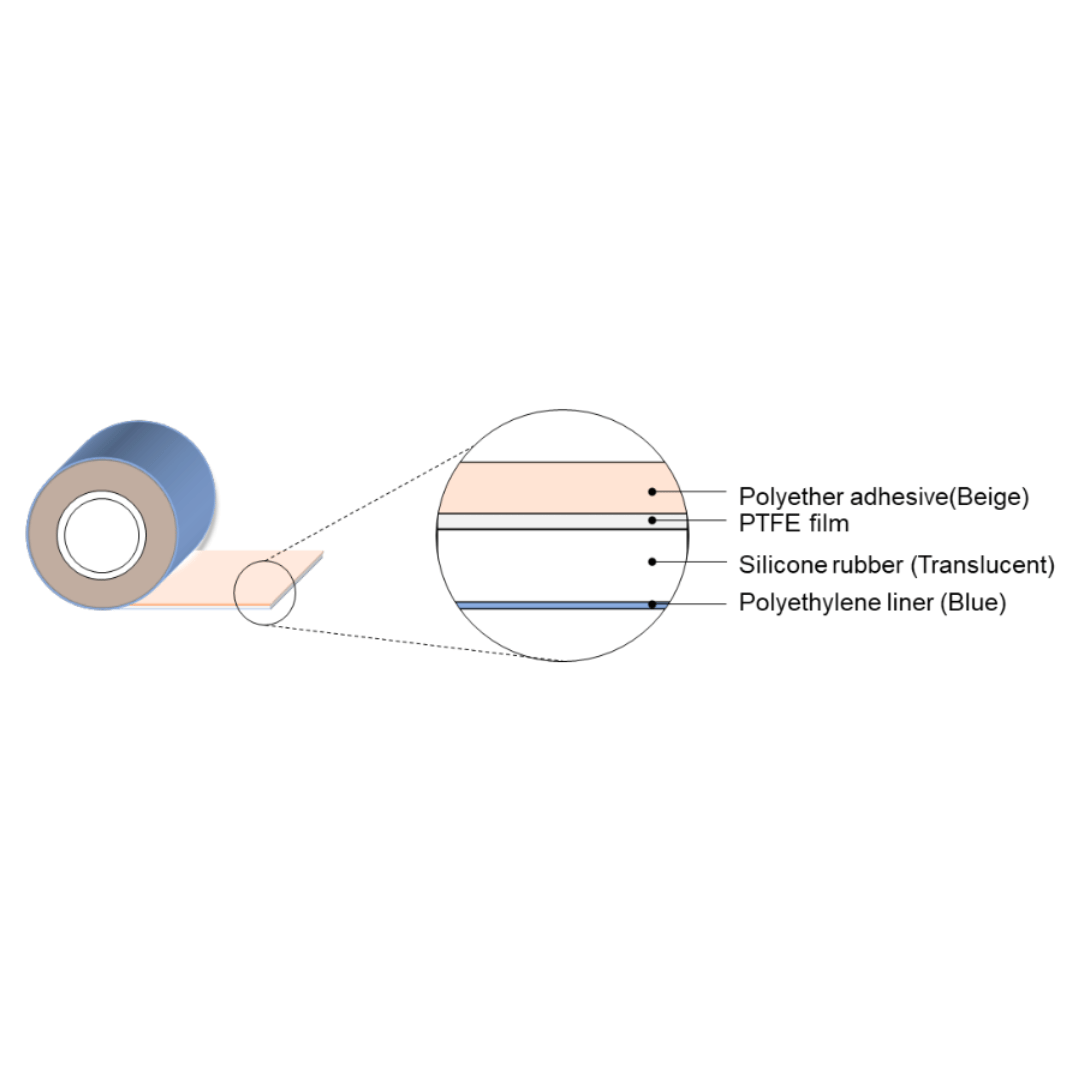

MARINE-SEAL 2 (Ref-DC260) is a double-coated, pressure-sensitive adhesive tape engineered for demanding marine environments. Its differential adhesion system features a strong-bonding polyether adhesive on one side and a silicone rubber layer on the other—both designed to leave no residue upon removal.

Thanks to its compressible construction and highly conformable silicone layer, MARINE-SEAL 2 excels in sealing complex or uneven surfaces where traditional gaskets may not be practical. The silicone rubber is 100% cured, highly hydrophobic, and has a low durometer, offering excellent reworkability and moisture resistance.

REACH and RoHS compliant, it's a clean, efficient solution for sealing tasks across a wide variety of marine applications.

Request Product Information

Key Benefits

Surface Adaptability

Ideal for both flat and irregular sealing surfaces with excellent conformability.

Differential Adhesion

Balanced bonding system ensures strong hold yet easy removal when needed.

Hydrophobic Properties

100% cured silicone layer actively repels moisture for maximum protection.

Clean Removal

No adhesive residue left behind, making inspection and maintenance simpler.

Technical Specifications

Designed for superior performance in complex marine environments

| Use Case | Moisture protection for complex or uneven marine surfaces |

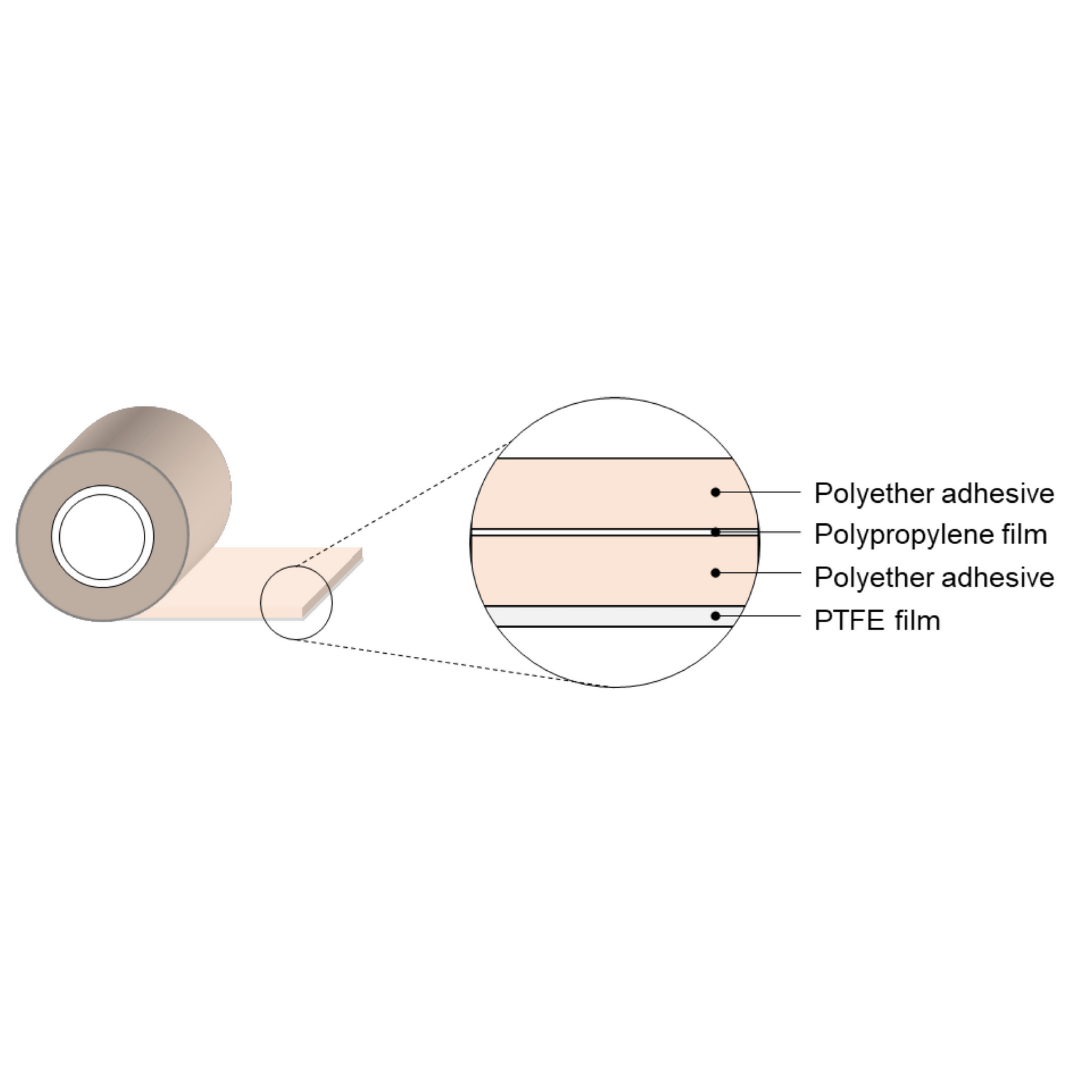

| Construction | Double-coated with silicone rubber & polyether adhesive |

| Sealing Method | Compressible for gasket-like functionality |

| Adhesion | Strong (polyether side) / Moderate (silicone side) |

| Weather Resistance | Excellent barrier to moisture and humidity |

| Residue After Removal | None |

| Ease of Application | Excellent – ideal for curved or contoured areas |

| Compliance | REACH & RoHS |

| Available Sizes | Custom widths available upon request |

Application Areas

Irregular Surfaces

Provides an effective seal on uneven surfaces where traditional gaskets are impractical.

Compression Seals

Creates reliable compression seals in applications requiring flexibility and reboundability.

Electrical Enclosures

Protects sensitive electrical components from moisture ingress in marine environments.

Hatches & Access Panels

Forms effective moisture barriers around frequently accessed panels and hatches.

Application Information

Proper Application For Best Results

-

1

Surface Preparation

Ensure surfaces are clean, dry, and free from oils or contaminants for optimal adhesion.

-

2

Measure & Cut

Cut MARINE-SEAL 2 to the required dimensions, allowing small overlap at joints where necessary.

-

3

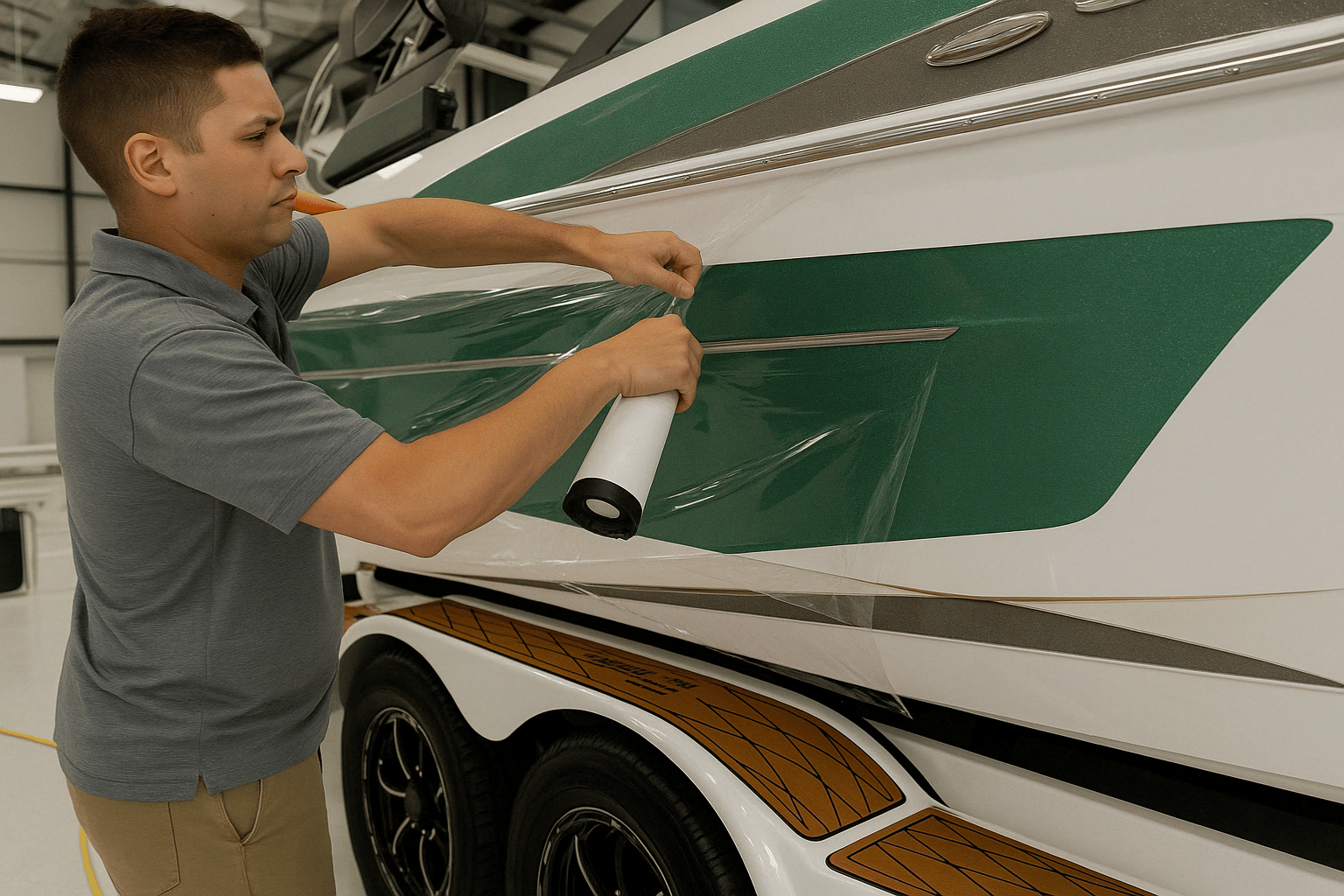

Apply The Tape

Position with the polyether adhesive side against the primary substrate, applying firm pressure to activate adhesion.

-

4

Compress For Sealing

When securing the second surface, apply even pressure to compress the silicone layer for optimal sealing.

Frequently Asked Questions

-

How does MARINE-SEAL 2 compare to traditional gaskets?

MARINE-SEAL 2 offers several advantages over traditional gaskets, including easier application on irregular surfaces, better conformability to complex shapes, and clean removal without residue. It eliminates the need for custom gasket cutting and provides reliable sealing with its compressible silicone layer.

-

Can MARINE-SEAL 2 be repositioned during application?

Yes, MARINE-SEAL 2 allows for initial repositioning during application. The differential adhesion system provides enough initial tack to hold the tape in place while allowing adjustment before final pressure is applied to create a permanent bond.

-

How well does it work on textured surfaces?

MARINE-SEAL 2 is specifically designed for textured and irregular surfaces. Its silicone layer conforms to surface variations, filling gaps and creating an effective moisture barrier even on uneven substrates. The compressible construction helps maintain contact with both mating surfaces despite variations in gap width.

-

What temperature range can MARINE-SEAL 2 withstand?

MARINE-SEAL 2 maintains its performance properties across a wide range of temperatures typically encountered in marine environments. The silicone rubber component provides excellent temperature stability, while the adhesive system remains effective in both cold and warm conditions commonly found on vessels.

Request Product Information

Get detailed specifications, pricing, and application guidance for MARINE-SEAL 2.